Scan the QR-code to get technical consultation immediately

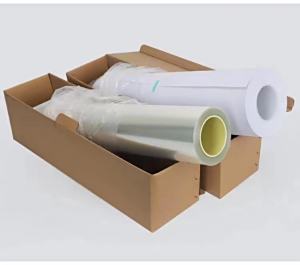

ZK-T30A-1 Film Protective Film

Product Introduction

Product Classification: Dry Film, Wet Film.

Product Specifications: 10µm*560mm*150m Other specifications can be customized.

Product Ingredients: A PE film with excellent light transmittance, a very strong adhesive layer and a smooth polyester stretch diaphragm.

Product Features

The protective film has good UV resistance and excellent light transmittance;

The protective film has the function of preventing scratches and anti-static;

Avoid dust and increase the service life of the film. It plays a role in protecting the photolithography film negative and increasing the service life of the film. It can adapt to the protection of 50μm circuit film and 1μm circuit glass chrome plate.

Product Care

During the production process, the film will inevitably be scratched by human factors and eroded by green oil solvent, which will reduce the service life of the film and increase the repair rate of the board. To improve this situation, most manufacturers have adopted the method of applying protective film to protect the film.

Facing the protective films on the market, they can basically meet the requirements of circuit board factories, but during use, we still need to pay attention to various matters. The laminating roller should be wiped frequently to keep the roller clean so that bubbles will not be generated during laminating.

Operation and Use

The operation of the protective film is not complicated. As long as the machine is stable, there will be almost no problems. It requires the machine pressure to be uniform and the speed to be stable. The roller must not have debris and gaps.

Please Note

After laminating, the film will be shortened by about 15 microns (24" film) due to the effect of internal stress, so try to press the short side when laminating.

Before laminating the diazo film, expose the newly developed diazo film once to allow the ammonia to evaporate completely before laminating.

Ensure that the pressure is horizontal and there is no tilt.