Zhongke Micro KEY High-Performance Gas-Phase Welding Fluid: Unleashing the Full Potential of Gas-Phase Welding Technology

Principles and Advantages of Vapor Phase Soldering (VPS) Technology

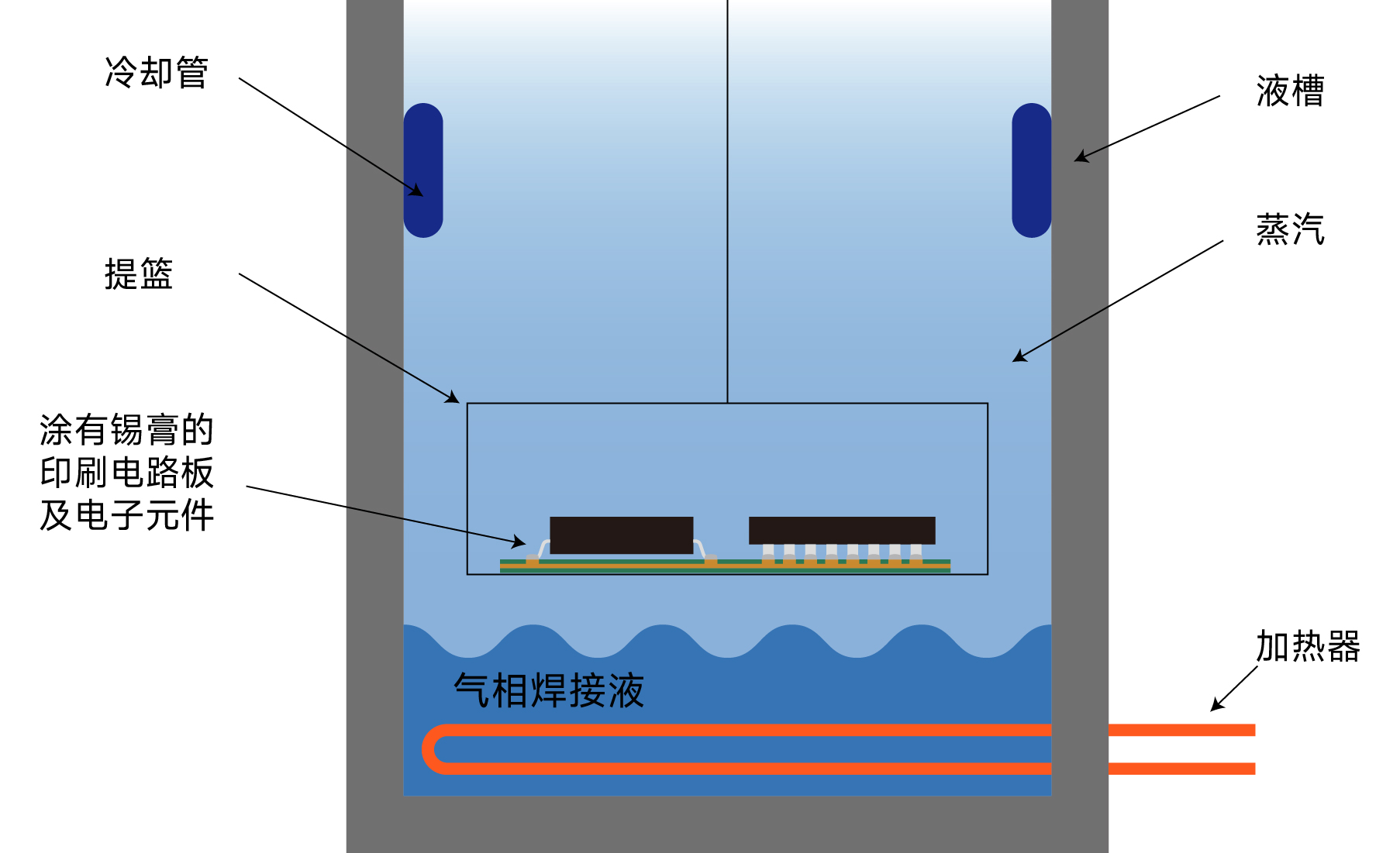

Vapor-phase welding, also known as condensation welding, is an advanced technology that utilizes the saturated vapor of specialized liquids with high boiling points and excellent thermal stability for welding. Its core principle lies in:

- Uniform Heating: Saturated vapor generated from boiling liquid uniformly and efficiently transfers heat throughout the immersed PCB assembly, completely eliminating localized temperature variations common in traditional reflow soldering.

- Low-Oxidation Environment: The vapor layer forms a natural barrier, significantly reducing oxidation of solder joints and components at high temperatures, resulting in brighter, more reliable solder joints.

- Handling Complex Challenges: Particularly suited for soldering high-density interconnect (HDI) boards, irregularly shaped components, large thermal mass components, or heat-sensitive parts. Its exceptional thermal conductivity consistency effectively prevents issues like warping and cold solder joints.

- Process Simplification: The entire soldering process occurs within an inert vapor environment, eliminating the need for complex multi-zone temperature settings. This provides a wider process window and simpler control.

Vapor Phase Soldering Fluid (VPS Fluid) is the key medium enabling this technology, with its performance directly determining soldering quality, process stability, equipment lifespan, operational safety, and environmental impact.

KEY Gas-Phase Soldering Fluid: Setting the Industry Standard

At Zhongke Micro, we deeply understand the core value of vapor phase soldering fluid. Our high-performance vapor phase soldering fluid series is specifically designed to meet the stringent demands of the modern electronics manufacturing industry for ultimate quality, exceptional stability, environmental compliance, and cost-effectiveness.

Our Core Strengths:

- Exceptional Thermal Stability and Extended Lifespan: Utilizing a carefully selected formulation and stringent manufacturing processes, the liquid maintains stability under prolonged high-temperature operation, resisting decomposition or the generation of harmful residues. This significantly extends service life while reducing replacement frequency and overall costs.

- Superior Soldering Performance: Optimized physicochemical properties deliver exceptional wettability, enabling perfect solder spread to form bright, full, defect-free joints (free from bridging or cold solder joints) with high reliability.

- Leading Environmental and Safety Characteristics:

- Low VOC / Halogen-Free Formulation: Committed to reducing environmental impact, meeting or exceeding the world's most stringent environmental regulations (e.g., RoHS, REACH).

- Environmentally Friendly Components: Prioritizes operator health, providing a safer workshop environment.

- Excellent User-Friendliness: Easy to operate and maintain.

- Wide Applicability: Carefully engineered formulations ensure compatibility with various mainstream lead-free and leaded solder alloys, fluxes, and common PCB substrates, providing a broad process window.

Our Gas-Phase Welding Fluid Product Line

We offer a diverse range of vapor phase soldering fluids to meet varying application scenarios and customer requirements:

The KEY Series vapor phase soldering fluids, featuring precisely engineered boiling points and exceptional thermal stability, comprehensively address soldering needs from routine electronic assembly to high-temperature specialized processes. Developed specifically to eliminate thermal damage and enhance joint reliability, they provide robust assurance for high-end electronics manufacturing.

1. KEY-138: Precision Low-Temperature Welding Specialist

Boiling point: 200°C

Core Values:

- Industry-leading ultra-low boiling point, perfectly suited for heat-sensitive components (such as MEMS sensors, flexible circuits, and LED packages).

- Effectively mitigates risks of thermal deformation and material aging, significantly improving yield rates.

- Uniform vapor layer encapsulation eliminates cold solder joints caused by temperature inconsistencies.

2. KEY-230: The Gold Standard in Lead-Free Processes

Boiling point: 230°C

Core Values:

- Precisely matched for mainstream lead-free solders such as SAC305 (melting point 217-220°C).

- Provides sufficient heat input to compensate for vapor heat transfer efficiency losses, ensuring complete solder melting.

- Compatible with equipment temperature control fluctuations.

3. KEY-140: High-Temperature, High-Density Board Solution

Boiling point: 275°C

Core Values:

- Breakthrough high-temperature performance addresses uneven heating issues in high-density interconnect (HDI) boards.

- Supports high-melting-point solder alloys (e.g., Sn-Sb) for large thermal mass BGAs and QFN packages.

- Enhanced vapor permeation capability eliminates voids in bottom solder joints.

4. KEY-150D: The Flagship Choice for Specialized Craftsmanship

Boiling point: 290°C

Core Values:

- Industry-leading heat resistance, compatible with specialized processes such as Au80Sn20 gold-tin solder.

- Exceptional oxidation resistance and thermal stability ensure consistent performance under extreme high-temperature conditions, minimizing harmful residues.

- Meets stringent requirements for high-end soldering applications.

Why choose KEY?

- Deep Technical Expertise: Leveraging years of accumulated expertise in electronic chemicals, we possess a profound understanding of process challenges and customer requirements.

- Continuous Innovation: We consistently invest in R&D to advance the performance of gas-phase soldering liquids and set new environmental standards.

- Rigorous Quality Control: From raw materials to finished products, we enforce a stringent quality management system throughout the entire process, ensuring consistent and reliable performance in every batch.

- Comprehensive Technical Support: We go beyond product supply to offer expert welding process optimization recommendations and timely technical assistance.

- Rapid Support Response: We ensure you receive the products and services you need, whenever and wherever you require them.

Discover the KEY gas-phase welding fluid best suited for your production needs!

Contact our engineers immediately: 138 2378 0855 (Mr. Wang)

Unleash the exceptional potential of gas-phase welding to elevate your welding quality and efficiency—choose KEY, choose a reliable partner!

LATEST NEWS

- Introduction to Immersion Cooling 2025-12-30 21:46:36

- Good News|Zhongke Micro New Materials Secures Third Place in the Industry Finals of the Longgang District Preliminary Round for the 17th China Shenzhen Innovation and Entrepreneurship Competition 2025-12-19 10:29:54

- Conquering the Summit of Wutong Mountain, Tempering the Spirit of Teamwork | Zhongke Micro New Materials' Autumn Team-Building Event at Wutong Mountain Concludes Successfully 2025-11-02 22:42:15

- Zhongke Micro KEY High-Performance Gas-Phase Welding Fluid: Unleashing the Full Potential of Gas-Phase Welding Technology 2025-08-07 14:46:00

- Zhongke Micro New Materials Recognized as National High-Tech Enterprise Innovation Engine Propels New Journey Toward Domestic Production of Fluorinated Materials 2025-03-19 17:54:11

- Electronic Fluorinated Fluids: The "Invisible Guardians" of the Tech Industry 2025-02-27 14:24:47

- Uniting Hearts and Minds to Chart Our Course Together Zhongkewei 2025 General Manager Annual Meeting Address Inspires and Motivates 2025-01-22 23:28:38

- Zhongkewei successfully passed the ISO 9001:2015 Quality Management System certification on June 4, 2021. 2021-08-16 17:00:19

- Keep safety in mind at all times and ensure safety is never compromised 2023-10-10 14:36:26

- Transition to digitalization and seize the opportunities of the digital economy 2023-10-12 15:51:07