Scan the QR-code to get technical consultation immediately

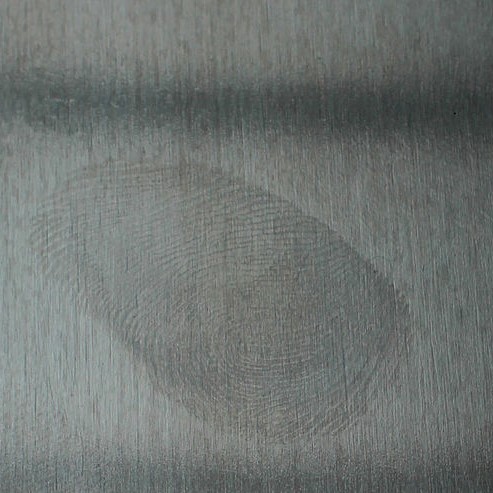

KEY-115D Anti-Fingerprint Coating on Glass

Product Highlights

| Contact Angle 120º max | Comply with RoHS Environmental Directive | Comply with REACH environmental directive |

| Suitable for Various Attachment Processes | Waterproof, Moisture-Proof and Corrosion-Resistant | Reduce Dust Adhesion |

| Wear Resistance | Suitable for Glass and Metal Surfaces | Strong Adhesion |

Product Features

- Compared with conventional fluorosilane, the wear resistance and smoothness have been greatly improved.

- Good durable anti-fouling and chemical properties.

- Easy to clean, high hydrophobicity, low oil adhesion

- Low dynamic friction coefficient, providing high-quality feel.

- Has good corrosion resistance and oxidation resistance.

- Excellent adhesion, forming a complete molecular structure on the surface.

- Good optical properties, high transparency, low viscosity.

- Extremely low surface tension, good hydrophobic and oleophobic effect (contact angle 120º max)

- Excellent friction resistance.

Industry Applications

|  |  |  |  |

| Mobile phone screen coating | Anti-fingerprint | Display coating | Self-cleaning | Anti-fouling |

This product can be applied to the surface of various inorganic silicate glass materials, such as screen glass, tempered glass film, automotive glass, bathroom glass, etc.

Performance Parameters KEY-115D

Item | Parameters |

Appearance | Colorless Transparent Liquid |

Density | 73°1.78g /m³,25℃ |

Viscosity | 0.8 mm² /s,25℃ |

Surface Drying Time | 10-20 s |

Actual Drying Time | 24H |

Volatility | Volatile |

Instructions for use

Before use, first use a dust-free cloth dipped in anhydrous alcohol as a cleaning agent to wipe the screen in one direction and multiple times until it is clean and dry. Finally, use a clean and dry dust-free cloth to wipe the glass thoroughly without any visible stains.

You can choose to use a variety of methods such as shower coating, spray coating, drip coating, and wipe coating (fast evaporation speed is a normal phenomenon).

Process: Can be baked at room temperature.

If baked, it is recommended to bake at 150 ℃ for 30 minutes, and all aspects of performance can reach the optimal state (suitable for mass production line application).

Please Note

The higher the surface cleanliness of the substrate before rubbing, the better the adhesion and the longer the duration.

The nano liquid will lose its effectiveness when exposed to water. Store it in a sealed container and avoid contact with water during use.

It is highly volatile. Please do not approach heat sources to avoid waste.

If the bottle mouth is opened and closed frequently, a smaller container should be replaced to reduce the volatilization caused by multiple openings.

The remaining coating liquid after use can be recycled for the next use. It is recommended to filter it with a filter as soon as possible and seal it in another bottle for storage.

Packaging Specifications

5KG、10KG、15KG、25KG

Storage and Transportation Requirements

Transport as non-hazardous chemicals and non-corrosive chemicals.

Storage temperature: -10~+25°C

Keep sealed, avoid direct sunlight and high heat.

Warranty in sealed state: 6 months.