Scan the QR-code to get technical consultation immediately

KEY-DLS-H330 Direct Plate-Making Photoresist

Product Highlights

Comply with RoHS environmental directive | High resolution, fine lines | High photosensitivity, short exposure time |

Good film stripping performance, the screen can be recycled | Excellent storage stability | Soft film to prevent ink seepage |

Scope of Application

High-precision printing, dot printing PCB, electronic products.

Product Characteristics

| Appearance | Blue viscous resin emulsion, solid content: 40% |

| Viscosity | 9,000mPa・s |

Preparation

Before applying the photoresist, first use the matching degreaser to clean and degrease the stencil, then clean the stencil carefully and dry it completely.

Preparation Method

After opening the can, please add 50-150 grams of pure water and stir for 3-5 minutes. Depending on the customer's situation, add 0.5g/1g of K2 diazo powder into the pure water and stir. After stirring evenly, pour the solvent into the photoresist and stir for 3-5 minutes. After the preparation is completed, let it stand for 8-12 hours before use.

Please Note

Photosensitive glue storage: Before sensitization, the storage temperature of the photosensitive glue colloid is best in a cold and dark place at 20℃. Do not store it in an environment above 25℃ or below 5℃, otherwise it is easy to produce chemical and physical changes, affecting normal use. Please store diazo in a refrigerator at 0-5℃.

Degreasing of the screen: Before applying the photosensitive glue, the screen should be thoroughly cleaned with a special degreasing agent to remove grease and dirt. After thorough cleaning and drying, high-quality screens can be obtained and the printing durability can be improved.

Diazo dissolution: Pure water or purified water should be used to dissolve diazo. If tap water is used directly, the minerals and water rust in the tap water will react chemically with the photosensitive glue, affecting the performance. In severe cases, the colloid will agglomerate and cannot be used normally.

Drying oven temperature: The temperature of the drying oven is best below 40℃. When it exceeds 40℃, the photosensitive glue is prone to thermal reactions, which reduces the resolution. The drying oven should have an exhaust device to discharge moisture in the box and improve the efficiency of complete drying of the screen. Check the temperature inside the oven every month to see if it is consistent with the set temperature. Check the temperature inside the oven every month to see if it is consistent with the set temperature.

Winter development: If the developing water temperature is too low in winter, it will cause poor screen development and reduced resolution. It is recommended to use warm water (25°C) for development.

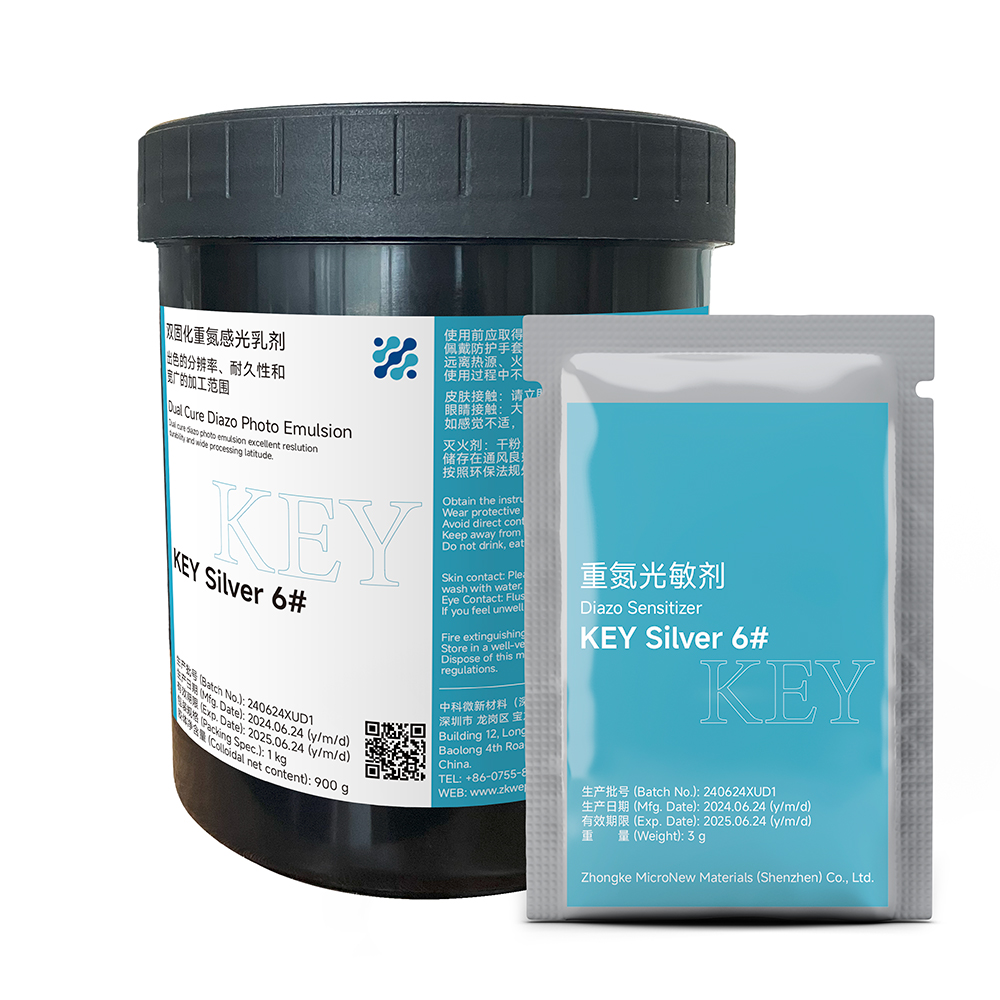

Packing Specifications

Black thick plastic can: 1kg/can, 5kg/barrel