扫码立刻获取技术咨询

KEY-113 Electronic Fluorinated Fluid (a replacement for 3M Novec™ 7000)

Product Highlights

Wide range of thermal management applications | Low surface tension | Low kinematic viscosity |

Insulation | Broad material compatibility | Low toxicity |

Low global warming potential (GWP) | Zero Ozone Depletion Potential (ODP) | Non-combustible |

It does not belong to volatile organic compounds. | RoHS PASS | REACH PASS |

Product Features

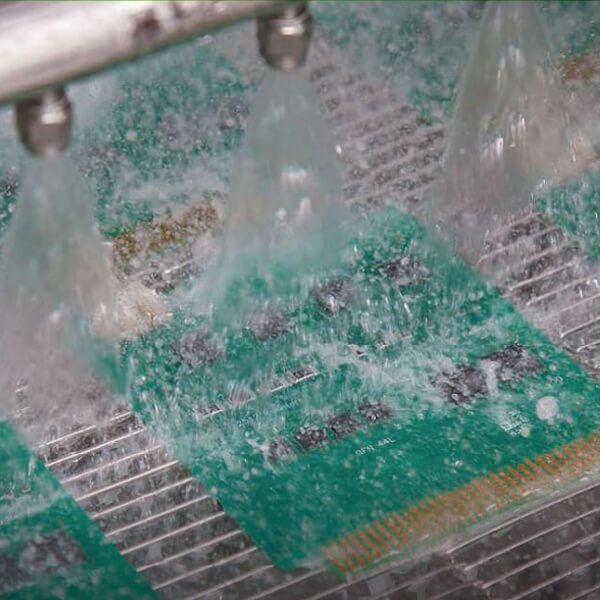

- Extremely low surface tension and viscosity enable excellent dispersion, spreading, and penetration into various crevices, providing superior flushing, wetting, and cleaning.

- Excellent electrical insulation allows cleaning under live conditions, expanding operational space.

- Moderate boiling point (35°C) facilitates use in various evaporative cycle cleaning equipment while also cooling components during the evaporation process.

- Non-hazardous, non-flammable, non-explosive, with no flash point or ignition point.

- Excellent flowability and volatility with no residue; provides effective dehydration treatment.

- Non-toxic, non-hazardous, and non-irritating.

- Environmentally friendly with an ODP value of 0 and extremely low GWP value.

- Post-cleaning liquid can be regenerated through distillation, reducing waste and saving costs.

Industry Applications

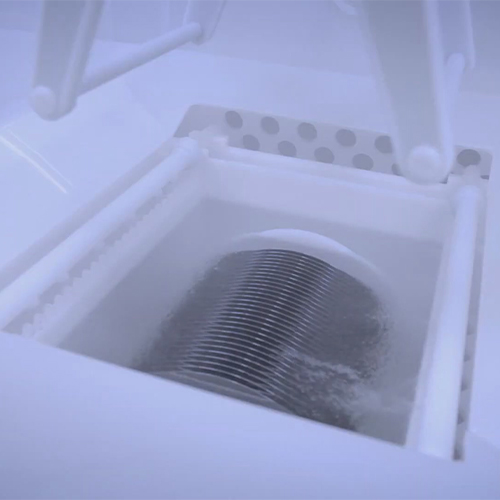

- Thermal conduction and cooling media for heat dissipation in computer servers, electronic components, power batteries, energy storage systems, and more.

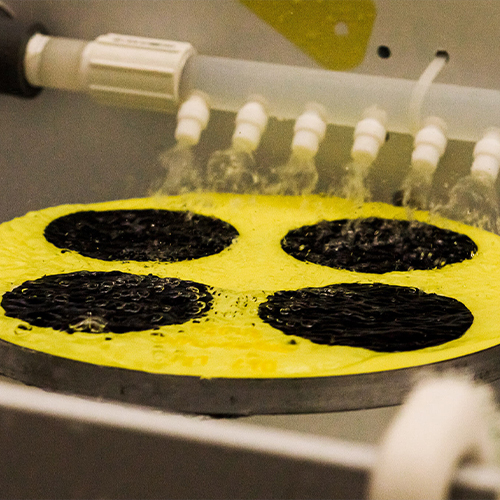

- Semiconductor manufacturing, chip fabrication, packaging and testing, laser etching.

- Cleaning and maintenance of electronic, electrical, and power equipment without power interruption or operational downtime.

- Providing insulation protection within high-voltage equipment.

- Cooling and lubrication during milling and grinding processes.

- Precision cleaning, dehydration, leak detection, and testing of electronic components.

- Solvent diluents, lubricant diluents, and other specialty solvents.

- Thermal shock testing fluid.

Physicochemical parameters

KEY-113

| Appearance | Colorless and transparent liquid | Surface tension | 12.4 dyn/cm | |

| Odor | Odorless | Thermal conductivity | 0.065 W/m·K | |

| Content | ≥99% | Dielectric strength | >25 kV | |

| Boiling point | 35℃ | Dielectric constant | 1.85 | |

| Pour point | <-120℃ | Solubility of water in liquids | <10 ppm | |

| Kinematic viscosity | 0.33 cSt | Flash point | None | |

| Density | 1.65 g/ml | ODP | 0 | |

| Specific heat | 0.22 cal/g ℃ | KB Value | - | |

| Refractive index | 1.28 | GWP | Low | |

| coefficient of expansion | 0.0011 cm³ /cm³ ℃ |

Remark:

Product properties at 25°C, excluding boiling point and freezing point.

Transportation and storage

Transport as non-hazardous and non-corrosive chemicals, and store at room temperature.

Keep sealed, avoid direct sunlight and high heat.

The product is sealed and has a 24-month warranty period.

Packaging specifications

|  |  |  |  |  |  |

| 5 KG | 10 KG | 15 KG | 20 KG | 25 KG | 50 KG | 100 KG |